How To Test An Idle Air Control Valve

Dan Ferrell writes about do-it-yourself car maintenance and repair. He has certifications in automation and control engineering science.

Ford IAC valve.

Author's ain photor

IAC motor or valve problems can show symptoms similar:

- erratic idling

- engine stalling

- surging

- high idle

- low idle

Although practically any problem that affects engine operation may affect idle speed, the two almost common causes of idle speed problems are:

- throttle position sensor (TPS) issues, and

- carbon buildup in the IAC motor air passages and throttle body.

Before checking or testing the IAC motor, permit'due south have a cursory look at how the valve operates, so that you know what to await for when checking the motor.

| Alphabetize |

|---|

| i. How the IAC Works |

| 2. Cleaning Carbon Buildup |

| 3. Testing the IAC Motor |

| four. Replacing the IAC motor |

Y'all tin find the IAC attached to the throttle body, which connects to the intake manifold.

Photo courtesy of Craig Hydes on needpix.com

ane. How the IAC Works

Your automobile's computer controls idle speed using information from diverse sensors and vehicle operating conditions. With this information, the computer either allows air to bypass the throttle plate or keeps it from doing and so. The computer controls the airflow using either an idle speed control (ISC) motor (usually institute in throttle body injection (TBI) systems), or an idle air command (IAC) motor or valve (In multiport electronic fuel injections (EFI) systems). Yous may see these names ISC and IAC used interchangeably. On some models, manufacturers may call this mechanism the air bypass valve.

IAC functioning is simple. The computer commands the pintle in the ISC motor or the IAC motor to motion in or out to allow more or less air to flow through when the engine is at idle.

Some older vehicle models may take a "fast idle" thermo valve that works without a computer to preform the same function as the ISC or IAC motor. The thermo valve uses a thermowax plunger that expands with heat and contracts when cool. Eventually, the valve's wax may leak and outset to cause high idle issues. In some cases, you may be able to accommodate the valve. But usually, a valve replacement is necessary. Consult your vehicle repair transmission to find out which system you accept.

If you lot don't have this manual withal, yous can buy i for your make and model from Amazon. Haynes manuals come with stride-by-step procedures for many troubleshooting, replacement and maintenance projects yous can practice at domicile. So yous'll go your investment back in a curt menses of time.

Apply carburetor cleaner to remove carbon buildup from IAC valve and throttle body air passages.

Writer'southward own photo.

ii. Cleaning Carbon Buildup

After a few years of operation, air passages within the throttle body and the IAC motor valve may accrue carbon buildup. Inspecting and cleaning passages is a simple procedure.

Scroll to Keep

Read More from AxleAddict

Before you start, though, be aware that on some models the throttle body and plate come up with a protective coating that makes it difficult for carbon to accumulate. In fact, trying to clean a throttle trunk and plate with special chemicals on these models can remove this protective layer and interfere with proper throttle torso performance and engine operation. If throttle diameter looks clean already, don't try to make information technology shine. If necessary, consult your vehicle repair manual.

To clean the IAC motor:

- Prepare the transmission to Park (automatic) or Neutral (transmission).

- Ready the ignition to the "off" position.

- Engage the parking brake and pop the hood open up.

- Remove any accessories, if necessary, to gain access to the IAC motor attached to the throttle trunk.

- Unplug the IAC motor electrical connector.

- Detach the IAC motor from the throttle trunk. On some models, you need to remove ii or three mounting bolts. On other models, you demand to unthread the motor itself from the throttle torso. If necessary, consult your vehicle repair manual.

- One time removed, position the device so the motor is pointing up and the air passages are facing you.

- Carefully spray the air passages with throttle body cleaner and wipe the orifices with a clean rag. Use a swab to reach into the valve passages for cleaning. Then, clean the residue of the IAC valve housing, including the mating surface. Repeat this step until the cleaning fluid comes out make clean from the device.

- Then, spray throttle body cleaner into the throttle body bypass passage.

- If information technology is safe, clean the throttle bore and plate with the solution as well. Make certain to consult your vehicle repair transmission for this.

- When reinstalling the IAC, replace the valve'south gasket.

- Reinstall whatever components you may have removed to gain access to the IAC valve.

The following video shows the location of the throttle torso and IAC motor, and some tips about cleaning both the throttle bore and plate and the IAC motor.

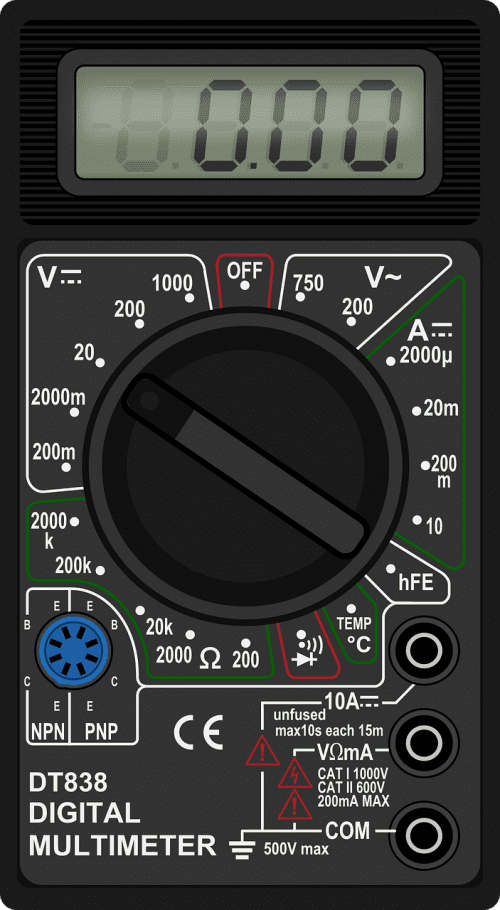

Utilize a digital multimeter to troubleshoot the IAC motor.

Photo courtesy of OpenClipart-Vectors on needpix.com.

iii. Testing the IAC Motor

Y'all tin can use a digital multimeter to check the electrical condition of the IAC motor and feed circuit. If your engine is equipped with a throttle body injection (TBI) system, it may have an idle speed motor. Cheque your vehicle repair manual, if necessary, for the testing procedure.

Here, nosotros're using an IAC motor with a unproblematic electrical configuration. Consult your vehicle repair transmission, if yours is different.

Checking the IAC valve internal circuitry:

- Set the ignition key to the "off" position.

- Unplug the IAC motor electrical connector.

- Plough the ignition key to the "on" position; don't start the engine.

- Ready your multimeter to 20 volts on the DC volts calibration.

- Connect your meter's blackness lead to the bombardment negative mail.

- With your meter's scarlet pb, probe the wires on the harness connector, the terminal side that leads to the computer.

- Ane of the wires should read between 10.5 to 12.five volts; otherwise, in that location's something wrong on that side of the circuit and the IAC motor is non getting whatever signal from the computer. Consult your vehicle repair transmission for the right specifications for your particular model.

- Turn off the ignition primal.

- Now switch your multimeter to the Ohms scale.

- Measure the resistance across the last of the IAC valve.

- You should get betwixt vi to 14 ohms of resistance, depending on your particular application; otherwise, replace the IAC motor.

Consult your repair manual for the correct specs for your particular model.

Checking for an IAC motor short circuit:

- Fix your digital multimeter to the Ohms scale and choose a setting college than 10,000 ohms.

- Connect ane of the meter leads to the IAC motor instance, and the other meter lead to each of the IAC valve pins at the terminal.

- Both readings should exist about x,000 ohms or more; otherwise, the valve's electrical circuit is shorted to the instance. If necessary, replace the IAC motor.

Consult your repair manual for the correct electrical value specifications for your detail vehicle brand and model.

Checking for IAC motor functioning:

You tin also cheque IAC motor operation using bombardment voltage.

- Unplug the IAC motor electrical connector.

- Remove the IAC motor from the throttle body.

- Connect battery voltage to the corresponding terminals on the IAC motor using jumper wires.

- The motor plunger should extend.

- Reverse the jumper wire connections on the IAC motor terminals.

- The plunger should retract.

If the motor doesn't respond properly to battery voltage, the device is faulty. If your IAC motor passes all the tests and you still suspect the motor is non operating every bit it should, you lot may want to check the harness connector and wiring for a possible short or open. Another possibility is a faulty control module or relay, depending on your particular vehicle make and model.

Keep in mind that there are many other sensors or systems faults that tin affect idle. Cheque this other post for other potential problems that can affect idle.

When replacing the IAC motor, use the role number or your vehicle make, model and engine size to get the correct replacement.

Photo courtesy of U.S. Air Strength photo/Airman 1st Class Larissa Greatwood.

four. Replacing the IAC Motor

If you lot demand to replace the IAC motor, in that location are a few simple recommendations you can follow to make sure you are getting the correct replacement for your application and installing it properly.

- Look for a part number on the IAC motor you want to supplant and use that to social club the new one.

- Compare the pintle shape from the former motor to the new one.

- If necessary, conform the pintle distance on the new device by measuring the distance on the old motor from the tip of the pintle to its base. Follow the instructions that come with your new IAC motor.

- If necessary, verify pintle diameter using a vernier caliper.

- Install a new gasket or O-ring with your new IAC motor.

- If your IAC motor uses an O-band, lubricate the band with a thin layer of transmission oil earlier installation.

Apply the repair transmission for your detail make and model to get the correct specifications for your tests.

Photo courtesy of Tim Dobson on Flickr.

Checking and testing an IAC motor is non difficult, and you can do information technology with a few simple tools. For most applications, you simply demand a digital voltmeter or a test lite, or both. Often, it is necessary to have the manual for your particular model to identify wires and pins you lot may need to probe during your troubleshooting procedure. Besides, your manual may have tests for your item IAC configuration.

Having the correct tools for the job is essential for a fast and expert repair. In this case, you only need a few tools y'all may already have in your toolbox. And having the manual will help you confirm circuit and device performance and, if necessary, proper repair of your IAC for your particular application.

This content is accurate and true to the best of the author's knowledge and is not meant to substitute for formal and individualized communication from a qualified professional.

© 2019 Dan Ferrell

How To Test An Idle Air Control Valve,

Source: https://axleaddict.com/auto-repair/IAC-Motor-Troubleshooting

Posted by: vereenwhising.blogspot.com

0 Response to "How To Test An Idle Air Control Valve"

Post a Comment